Resources

Insights

Does your High-Throughput Screening workflow demand 2D and 3D Cell Models? Advance your Cardiac Research with the VOLTA Scanner

Case Study

Insights

VOLTA Scanner: A Turnkey, Optical Kinetic Plate Reader for Cardiac Safety Testing

Case Study

Insights

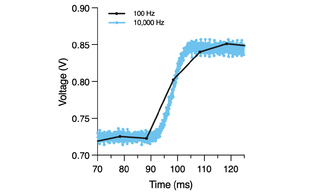

Bursting with Benefits: Optophysiology with BeRST Voltage Sensitive Dye

Case Study

Insights

Lumencor at Photonics West 2025: Advancing Insights with the Power of Light

Video

Insights

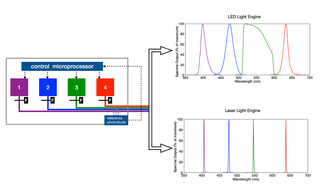

White Paper: Spatial Light Output Characteristics of Solid-State Light Engines

White Paper

Insights

Webinar: Safeguarding the Heart in Drug Discovery

Video

Insights

Lumencor’s ZIVA Light Engine for Yokogawa CSU-W1 featured at MBL’s Advanced Research Training Courses

Product News

Insights

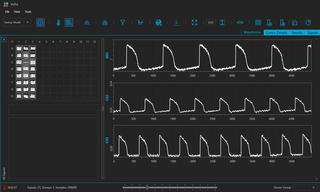

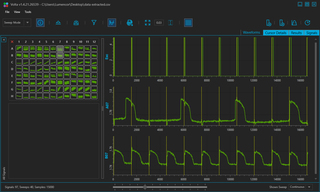

VOLTA Scanner: High-Throughput Cardiomyocyte Electrophysiology with an Optical Pacemaker

Case Study

Insights

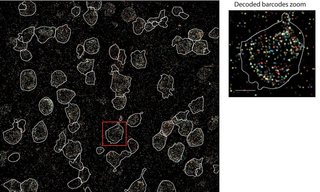

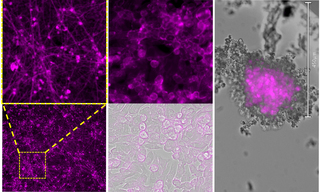

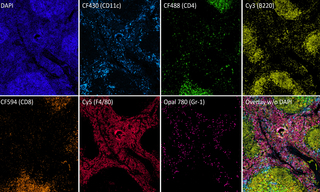

Multiplexed Fluorescence Detection with the new SPECTRA X Light Engine

Case Study

Insights

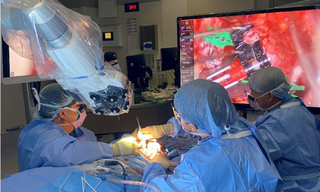

Solid-State Illumination for Intraoperative Imaging with the SPECTRA Light Engine

Case Study

Insights

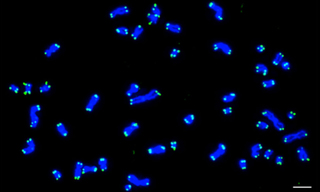

Case Study: Solid-State SOLAs Light Up FISH (Fluorescence In Situ Hybridization)

Case Study

Insights

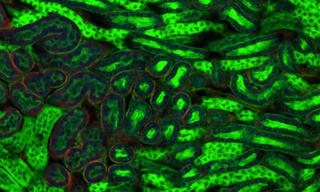

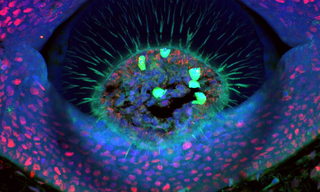

Optical Reconstruction of Chromatin Architecture using the CELESTA Light Engine

Case Study