Engineered for Surgical Precision: Illumination for Minimally Invasive and Robotic-Assisted Surgery

Lumencor was the first global supplier to replace 300 and 400W Xenon with a solid-state lamp replacement for minimally invasive robotic surgery. Today, we deliver custom-engineered white and color-selective light (Lumencor’s AURA and SPECTRA Light Engines)for applications including neurosurgery, gastrointestinal surgery, and advanced endoscopy, among others.

Features:

- Solid-state light sources including LEDs, lasers, and proprietary light pipes

- White light of required CRI, CT

- ~20W of UV, VIS and/or nIR

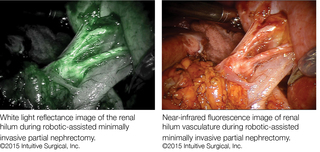

- nIR excitation for enhanced vascular visualization and FDA-approved fluors

- Tailored control of angular light distribution

Lumencor Light Engines are optimized for optimal visualization, precision metrology and robustness. With spatial, temporal and spectral control as well as unmatched reliability, Lumencor enables next-generation imaging and surgical tools that offer the best of brightness, contrast, stability and longevity.

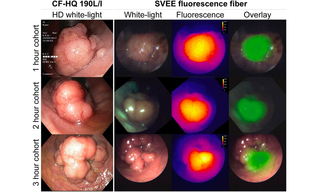

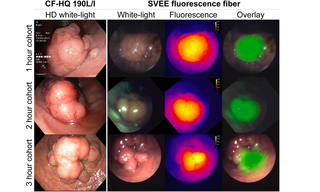

The identification of tumors during surgery or interventional endoscopy relies on visual inspection and palpation. Tumor tissue is sometimes difficult to distinguish from healthy tissue. So surgical resection of tumor is incomplete in up to 40% of procedures1.

This has medical as well as financial implications, impairing patient treatment outcomes. Combining highly sensitive imaging systems with tumor targeted imaging agents to visualize tumors during surgical or interventional procedures in real-time enables more sensitive and accurate tumor detection1.

1Lamberts et al. (2016) Clin. Cancer Res.; Koller et al. (2018) Nat. Comm.; Harlaar et al. (2016) Lancet Hepatol.; Nagengast et al. (2017) Gut; Tjalma et al. (2020) Gut; Hartmans et al. (2018).

Lumencor is synonymous with High Quality: We’re committed to sustainable, best-in-class products, produced in the United States.

Safety, product performance, exceeding customer expectations and continual improvement of the quality management system are our primary goals. Light Engines and Light Engine accessories are each designed and manufactured in Beaverton, Oregon in the United States under an ISO 9001:2015 certified quality management system. Each product ships with a unique certificate of conformance stating its compliance to Lumencor’s manufacturing processes and performance criteria.

Laboratories (UL) and TÜV SÜD America:

•All Lumencor’s standard Light Engines are TÜV SÜD America CB and cNRTLus certified, CE marked, UKCA marked, REACH, and RoHS compliant.

• UL accreditation gives Lumencor the ability to test Class 1 and Class 4 laser devices utilizing the IEC/ EN 60825-1:2014 standard. This enables Lumencor to obtain CB certification for all laser products. This certification is used with Laser Notice No. 56 for all necessary FDA/CDRH reporting and submissions.

• Lumencor’s on site Testing Laboratory affords in-house capabilities for all product safety and regulatory testing. In-house testing means weeks of time for full regulatory compliance and complete documentation and traceability, not the many months outside agencies typically demand. This greatly reduces time-to-market for all our products.

• Official product certifications testing is conducted in our IECEE CTF accredited testing laboratory. Lumencor’s Testing Lab has a full ISO/IEC 17025 Quality Management System and is audited annually by the accrediting agencies issuing certifications.

What can Lumencor do for you?

We’re here to illuminate the possibilities.

- Aug 01, 2025